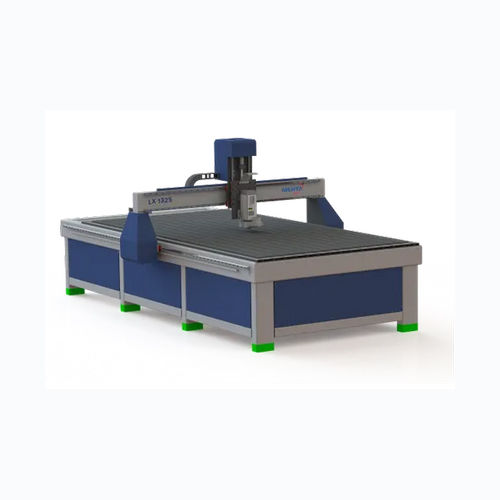

About CNC Router Wood Carving Machine

Product details

- Cutting Tool Diameter : 3 to 20 mm

- Distance between Bed and Gentry : 200 mm

- Driving System : Stepper Motor

- Maximum Traveling Speed : 20 mtr/min

- Outer Dimension : 2002 x 3150 x 1541 mm

- Power Supply : AC 420V/3PH

- Repeated Location : 0.025 mm

- Spindle : 6 kW Air Cooled (HSD Italian)

- Working Area (X, Y, Z) : 1300 x 2500 x 200 mm

- Operating System : DSP - Hand Held Controller

- Weight : 875 Kg

- Model Name/Number : LX 1325

- Spindle Speed : 18000 RPM

Precision Woodworking for Industrial NeedsDesigned for demanding woodworking environments, this CNC router offers reliable, high-speed carving suitable for mass production. Its advanced AC motor and sturdy metal construction guarantee longevity and minimal maintenance, making it an essential asset for manufacturers seeking efficiency and consistency in their process.

Automated Control with PLC TechnologyThe integrated PLC control system automates complex carving sequences, reducing manual intervention and ensuring repeatable accuracy. Ideal for businesses aiming to optimize workflow and achieve consistent product quality, this technological feature also helps reduce operator fatigue and operational errors.

FAQ's of CNC Router Wood Carving Machine:

Q: How does the PLC control enhance the operation of the CNC Router Wood Carving Machine?

A: PLC control automates the carving process, allowing precise execution of complex patterns and sequences with minimal human supervision. It streamlines workflow, reduces error rates, and boosts productivity for industrial wood carving applications.

Q: What types of industrial processes can this CNC router handle?

A: This CNC router is suitable for a broad range of industrial wood carving tasks, including panel construction, intricate engravings, furniture production, and mass-scale decorative work, thanks to its high-speed spindle and robust build.

Q: When should a business consider using a high-speed CNC router for wood carving?

A: Businesses should invest in a high-speed CNC router when they require frequent, precise and large-volume wood carving for manufacturing or custom woodworking, where efficiency and accuracy directly impact profitability.

Q: Where can this CNC Router Wood Carving Machine be installed?

A: Owing to its substantial size and weight, the machine is best suited for installation in dedicated industrial workshops or manufacturing facilities with ample space and appropriate electrical infrastructure.

Q: What is the process for maintaining the CNC router to ensure optimal performance?

A: Routine maintenance includes cleaning the machine, inspecting and lubricating moving components, calibrating the PLC system, and ensuring the spindle and motor remain unobstructed. Following manufacturer guidelines maximizes longevity and reliability.

Q: What are the benefits of choosing an automated, high-speed wood carving machine?

A: Automated, high-speed wood carving machines significantly reduce operational time, improve precision, and permit complex designs to be produced consistently. These advantages lead to increased throughput and improved product quality.