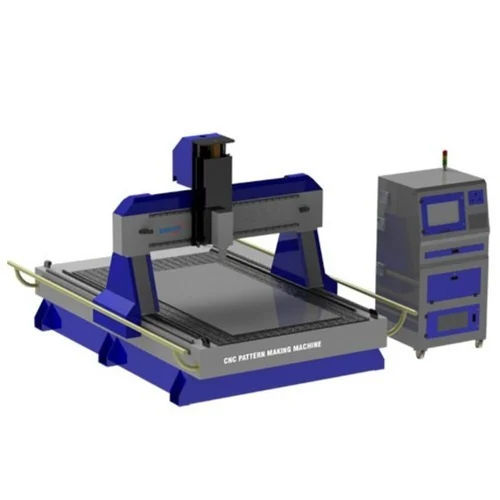

About CNC Wooden Pattern Making Machine

CNC Wooden Pattern Making Machine is a computer-controlled woodworking machine used to create intricate wooden patterns for various applications such as furniture design, interior decoration, and architectural mouldings. CNC Wooden Pattern Making Machine is designed to precisely cut, carve and shape wood into various designs and patterns, using advanced computer software and cutting tools. It offers high accuracy, efficiency, and versatility, making it ideal for producing complex and detailed wooden patterns.

Product details

- Driving System : Yaskawa AC Servo Motor 5.39 nm Torque

- Maximum Travelling Speed : 25 mtr/min

- Maximum Working Speed : 15 mtr/min

- Operating System : NC Studio Software with PCI controller

- Spindle Power : 6 KW, Air Cooled (HSD Italian Spindle)

- Spindle Speed : 18000 RPM

- Table Structure : Rigid Steel Frame Structure

- Transmission : X and Y Axis Transmit by Rack & Pinion with timing pulley & belt mechanism

- Travelling Area : 1200 x 1200 x 600 mm

- Working Area : 1200 x 1200 x 500 mm

- Working Voltage : AC 440 V, Three Phase, 50 Hz

- Model Name/Number : P-1212

Superior Precision and AutomationOur CNC Wooden Pattern Making Machine leverages PLC control to deliver outstanding accuracy and repeatability for industrial pattern manufacturing. Its high-speed automatic function increases efficiency, making it ideal for businesses seeking quick turnaround and consistent quality.

Robust Build and Reliable PerformanceConstructed from durable metal and fitted with an AC motor, this machine ensures long-term reliability and powerful performance. Its electric power source and robust design allow for seamless integration into industrial environments with demanding workloads.

Comprehensive Support and WarrantyWe stand behind our products with a one-year warranty and comprehensive support services. As an exporter, service provider, and trader in India, we ensure our clients receive not only high-quality machinery but also the technical assistance necessary for uninterrupted operation.

FAQ's of CNC Wooden Pattern Making Machine:

Q: How does the CNC Wooden Pattern Making Machine enhance industrial pattern manufacturing?

A: The machine utilizes PLC control and automatic operation to ensure high-speed and precise pattern production, reducing manual intervention and improving overall efficiency in industrial processes.

Q: What materials can be processed using this CNC machine?

A: This machine is specifically designed for wooden pattern making, utilizing its robust metal structure and high-speed AC motor to handle a variety of woods commonly used in industrial applications.

Q: When should routine maintenance be performed on this machine?

A: Regular maintenance, such as cleaning and checking mechanical components, should be carried out every few weeks based on usage intensity to maintain optimal performance and prolong the machine's lifespan.

Q: Where can this CNC Wooden Pattern Making Machine be installed?

A: Owing to its dimensions of 1200x1200x600 mm and electric operation, it's suitable for installation in most industrial workshops or factories across India and can be easily accommodated in standard workspace settings.

Q: What is the installation process for the CNC Wooden Pattern Making Machine?

A: After delivery, installation involves positioning the machine at the desired location, connecting it to a 440V electric power source, and configuring the PLC control system-typically handled by trained technicians as part of our after-sales service.

Q: How is the machine operated for pattern-making tasks?

A: Operators program the required designs into the PLC system, after which the machine automatically produces wooden patterns with high speed and accuracy, minimizing human error and maximizing productivity.

Q: What are the key benefits offered by this machine to businesses?

A: Businesses benefit from automated high-speed pattern production, reduced labor costs, precise repeatability, and comprehensive support-including a one-year warranty-making it a valuable asset for industrial manufacturing.